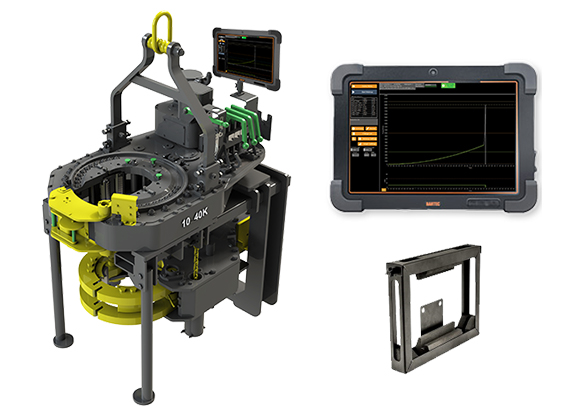

TORQUE/TURN MONITORING AND CONTROL SYSTEM

TORQUE/TURN MONITORING AND CONTROL SYSTEM CANADA / USA Origin by McCoy

Newest Features:

- Pipe Connection Library

- Multiple Language Capabilities

- View multiple joints in makeup screen

Functions:

- Monitors torque, turns, and rotation speed during make-up

- Controls based on final torque or final turns. Includes calibration management system

- Includes automatic “Start Recording” and “Dump Valve Release”

- Includes automatic descriptive comments with optional override

- Option to accept or reject connection on delta turn

- Easy graphical report creation and printing of reports with one button

- Controls speed during make-up (optional)

- Available with optional pressure test system

Analyzes Make-up to Determine:

- Conformance with thread manufacturer’s specification

- Shouldering point for premium connections

- Shouldering time, delta torque, delta turns

- Reviews results from previous make-ups

Specifications:

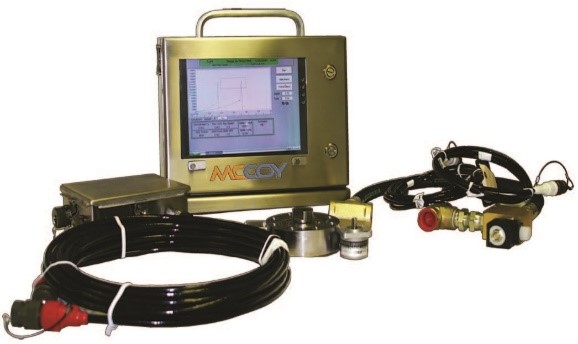

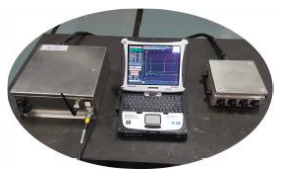

- Computer: Laptop running Windows in stainless steel enclosure

- Sampling Frequency: User defined from 1 to 8,000 Hz

- Recording Frequency: Based on delta torque and user defined delta time

- Response Time: Electronics: < 0.5 ms

- Hydraulic dump valve: typical 10 to 30 ms

- Final Torque: Average = Optimum torque +/- 1%

- Operating Temperature: 40° to 122°F (computer);

- -22° to 180°F (junction box)

- Torque Accuracy: Typically,

- Turns Accuracy: +/- 1 pulse of turns counter

- Pressure Accuracy: Typically,

- ATEX Certified Units

- Used for hazardous and non-hazardous locations