Fill-up and Circulating Tool

DrawWorks, L.P. AutoFill Casing

CANADA / USA Origin by McCoy

• Formed in 1996

• 65 years of engineering experience in design of downhole tools

• 30+ patents in the field of surface and downhole oil field equipment

• First development – AutoFill Casing Fill-up and Circulating equipment

• Hundreds of Autofill’s Worldwide

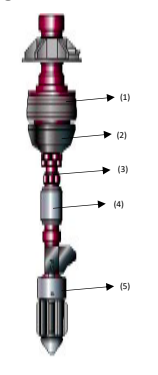

DrawWorks, L.P. AutoFill Casing Fill-up and Circulating Tool

1) Rig Adapter

• Top Drive Adapter

• Available in any connection to connect to the top drive

• Conventional Rig Adapter

• Allows the tool string to be connected to the hook of the traveling block of a conventional rig (rotary rig).

2) Push Plate Sub

• Prevent slip type elevators from getting stuck on the casing.

3) Spacers

• Used to space out the seal unit for different bail lengths.

DrawWorks, L.P. AutoFill Casing Fill-up and Circulating Tool

1) Cup Seal

• A passive seal requiring no actuation

• Rotates with casing

2) Nylon Gage Ring

• Will not damage the threads of the casing connection

• Does not leave shards of metal in the connection like aluminum or brass

• Rotates with casing

3) Quick Connect

4) Flex Hose

5) Auto Valve

* Cup Seal and Gage Ring are Free to rotate while casing is spinning.

DrawWorks, L.P. AutoFill Casing Fill-up and Circulating Tool

• Auto Valve

• Simple and reliable

• Ball valve is not subject to erosion

• Full opening for fill-up, circulating and flow back

• Once removed from the casing it immediately closes

DrawWorks, L.P AutoFill Casing Fill-up and Circulating Tool

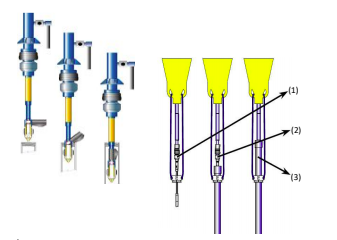

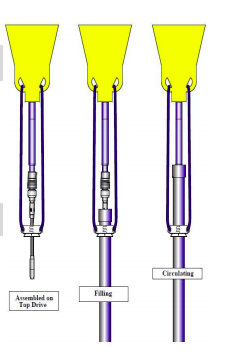

1) AutoFill system hanging from the top drive or traveling block.

2) AutoFill in the casing filling position with the fill-up valve only inserted into the casing

3) AutoFill with the seal inserted into the casing - can circulate or take fluid

Note:

The seal unit will normally be spaced out so that it is in the elevators, we have shown it above the elevators for illustrative purposes only.

OPERATING LIMITS

This tool has been designed to work within the operating limits described in this manual. Failure to follow the ratings and guidelines can have serious consequences. Please read and follow all instructions and warnings.

TABLE 1

Basic Operating Parameters

| Tool Size | MAX. TEMP. (OF) |

| 4-1/2” to 5-1/2” | 200 |

| 7” to 7-5/8” | 200 |

| 8-5/8” to 20” | 200 |

Table 2

Flow Rate Through AutoValve

| AUTOVALVE SIZE | BPM MAX. |

| 3-1/2” Fill-Up Tool | 4 |

| 4-1/2” to 5-1/2” | 5.5 |

| 7” & 7-5/8” | 12 |

| 8-5/8” to 20” | 20 |

| 16” to 30” | 20 |

WARNINGS:

Pressure applied to the tool while the seal is inside the casing (circulating) results in a piston force acting upward on the tool, and the spacer joints. This upward force is equal to the inside area of the casing times the pressure being applied and can approach a quarter of a million pounds (250,000 pounds). For this reason, the tool cannot be used at maximum rated pressure with a combination of spacer lengths exceeding the values listed in TABLE 8 (page 4.5) “Maximum Circulating Pressure and Pressure Rating with Spacer Joints.” Should these values be exceeded, spacer joints will fail causing damage to equipment and injury or death to those on or around the rig floor.

DrawWorks, L.P. “AUTOFILL™” CASING FILL-UP, FLOW BACK, AND CIRCULATION SYSTEM CANADA / USA Origin by McCoy

AUTOVALVE

During the fill-up process the unique design of the AutoValve allows the valve to open as soon as the valve enters the casing. A fully opening ball valve system prevents erosion that is common in other valve systems. The Immediate opening of the flow of mud through the ball allows for faster fill up of casing. When the AutoValve is removed from the casing, the valve will automatically close.

Once the Handle of the AutoValve is inserted into the upper end of the casing joint the mud pump can be started. Regardless of the fill rate, the maximum Fill-up pressure should not exceed the pressure rating of the Hose Assembly. When filling the casing using “Side Door” elevators care must be taken not to exceed the Maximum Circulating Pressure and Pressure Rating with Spacer Joints (page 4.4), since the Cup Seal is inside the casing while filling the casing.